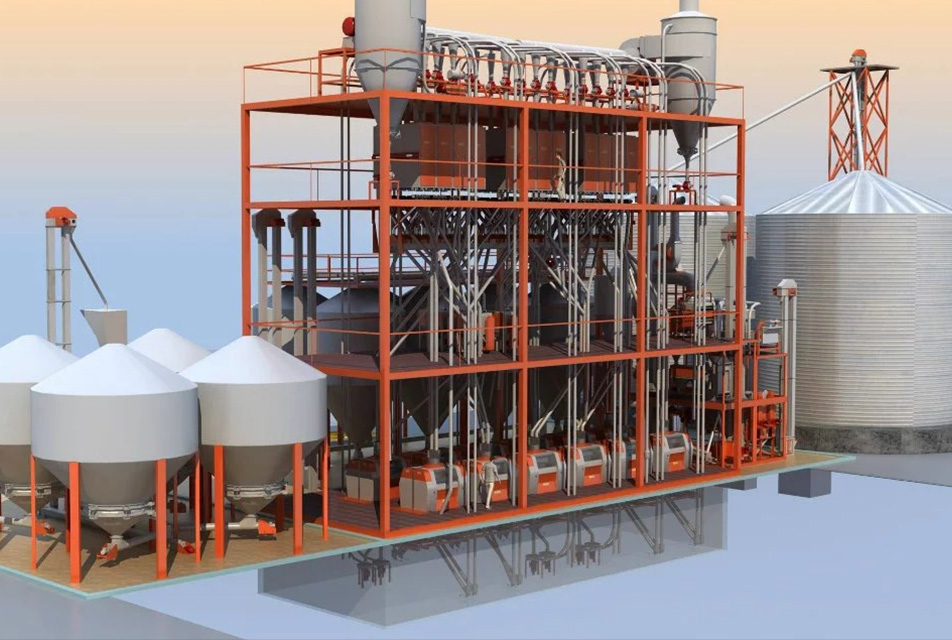

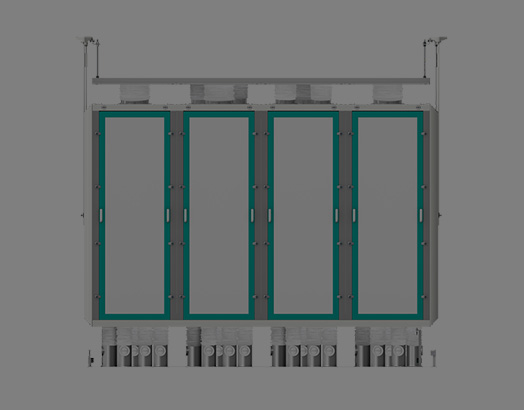

Series of the large scale complete set of the flour milling equipment with steel structure: This series of machinery is designed as steel structure containing high square plansifter and new style of pneumatic roller mill. They are developed and produced basing on our engineers’ hard work by absorbing the essence from the flour machinery producers all over China. With advanced technology,perfecttechnic combination, little area covered, good effect of classification, high qualityof flour, high flour extracting rate, short cycle of construction, low cost and simple structure and rapid result, they are the first choice for mid or large processing plants, where graded flour and special flour can be produced and standard flour, perfect flour can be produced in the mean time.

Sticks, stones and other such impurities are removed from the wheat. Then, the whole pure wheat is sent to the conditioning tank for further processing.

At this stage, the wheat is soaked in water in order to easily remove the bran. Conditioning is done prior to milling to ensure uniform moisture content throughout the grain. The moisture helps prevent the bran from breaking down during the milling process.

This is a particularly important stage where conditioned and cleaned wheat is mixed to produce the desired type and quality of flour.

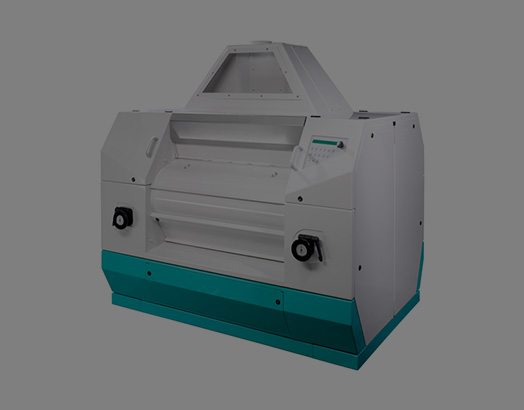

The grains then pass through a series of rolls that rotate at different speeds. The bread rolls separate only the small wheat grains in order to separate the inner white part from the bran.

Here, the ingredients are mixed to produce different flours. For example, a mixture of wheat bran and white flour produces whole wheat flour.