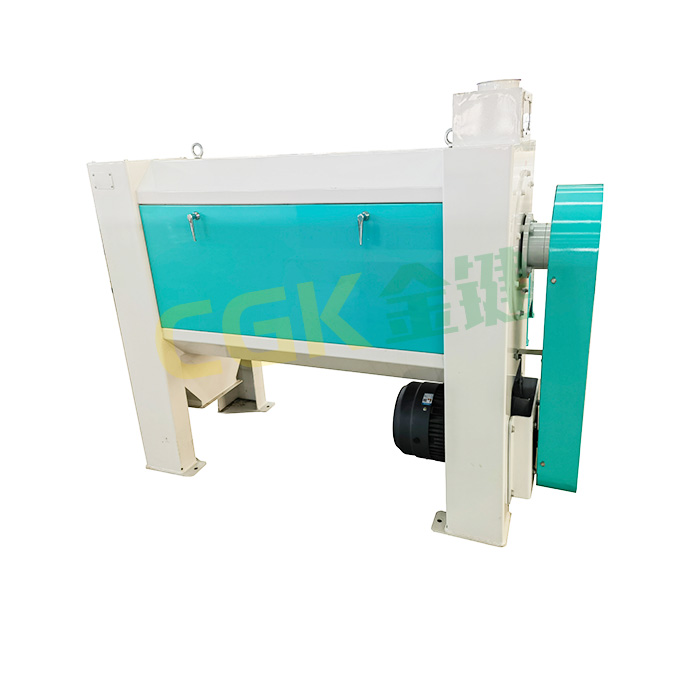

The main working components are the emery wiping plate and emery cylinder rotating on the rotor. A grinding chamber forms between them. After the wheat enters the grinding chamber, the surface of it is processed under the grinding of the rotating emery wiping plate and the emery cylinder. The airflow ejected from the blades inside the rotor blows away the impurities in time. and the adjustment device can change the grinding intensity.

Mainly used in wheat milling plants, it can reduce the ash content of raw wheat, effectively remove fungal toxins such as sickle, vomitus, yellow yeast, gibberellus, etc., and reduce corpse-breaking insects and pesticide residues. Extend the storage time of finished products.

|

Model |

Capacity(t/h) |

Power(kW) |

Air volume(m³/h) |

Dimension(L*W*H) |

|

TNPS-90 |

10-15 |

15 |

1500 |

1801*956*1680 |

|

TNPS-90*2 |

20-30 |

15*2 |

3000 |

1801*1912*1680 |